Each of these large, fast (short focal ratio) mirrors is a product of the Lab's unique strategy of spin-casting glass. A mold is built into the base of a giant oven, glass is then carefully weighed and placed into the mold. The top to the oven is brought over the mold and the entire oven rotates as the glass is melted in place. The oven spins at the proper rate so as to bring the liquid glass into very nearly the curve needed for the telescope's mirror. It continues to spin while the glass slowly cools and anneals.

| |

| The Mirror Lab's rotating oven. |

There are currently three mirrors sitting in the lab. The smallest of them is the 6.5 meter that was cast for the San Pedro Mártir Observatory in Baja California, Mexico. As you can see from the short video clip below it is literally hanging around waiting for its chance to get polished.

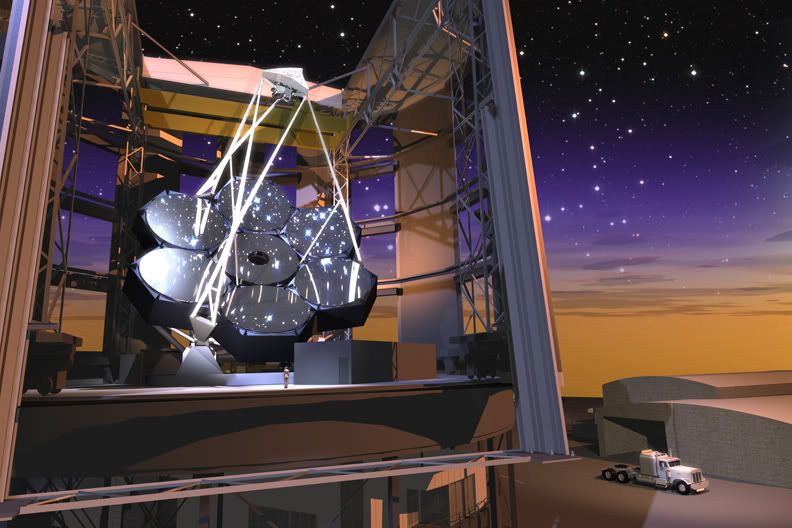

There are two mirrors already on deck part way through the polishing process in the lab. The first is one of the seven (yes, SEVEN!) mirrors that will make up the Giant Magellan Telescope. The people behind the GMT hope that when it is completed the it will be the first of the next generation of epically large telescopes - a telescope so big that will make the Palomar 200" and even the 10-meter Keck telescopes look small. Here is a visualization of how it will end up looking:

|

| Credit: GMT, Todd Mason |

|

| Photo by Mark Lane |

The second of the seven mirrors will be cast early next year. Between now and then technicians will begin the process of building the mold. They will then weigh and place hunks of glass like this one into the mold:

Here's a video from the University of Arizona featuring Roger Angel, the brains behind the whole spin-casting method, explaining a little bit about the process and the GMT:

Also currently being polished in the Mirror Lab is the 8.4-meter primary mirror for the Large Synoptic Survey Telescope. The LSST will be the world's first wide-angle survey telescope. I believe that the LSST will do more to revolutionize astronomy than any other telescope in existence, under construction or on the drawing boards. From the LSST website:

The 8.4-meter LSST will survey the entire visible sky deeply in multiple colors every week with its three-billion pixel digital camera, probing the mysteries of Dark Matter and Dark Energy, and opening a movie-like window on objects that change or move rapidly: exploding supernovae, potentially hazardous near-Earth asteroids, and distant Kuiper Belt Objects.In order to have such a wide-field telescope that can produce sharp images across its field of view, it needs to have a rather complex set of optics. As you can see from the visualization below, even the telescope's primary mirror needs to be fashioned to an unusual shape:

|

| Credit: LSST, Todd Mason |

The unusual shape of the glass proved to be difficult to photograph, but this short video I shot hopefully shows it off:

The tour of the Mirror Lab that I was on was expertly given by Dean Ketelsen (be sure to check out the cool blog that he and his wife write: here). Public tours are available. I recommend them for anyone interested in telescopes or astronomy. After all, the Mirror Lab is the birth place of some of the most productive telescopes working today and coming tomorrow.

Awesome! Is there some "magic" about the 8.4m size? It shows up a lot.

ReplyDeleteYes, there is. 8.4 is the largest sized mirror that they can hold without building a new oven. That size was chosen because at the time the largest single-disk telescope mirror was the 8.3 meter mirror for the Subaru telescope. UofA had to go a bit bigger to be the biggest.

ReplyDelete